- Company

- Services

- Products

- Spare Parts

- Logistics

- Training/Classes

- Contact

- Careers

MSHS in-house mechanical engineering team designs solutions that enhance the lifecycle of industrial equipment and machinery.

Using the latest computer-aided technology and solid modeling designs, our highly-specialized engineers analyze and develop custom products for customer-specific applications.

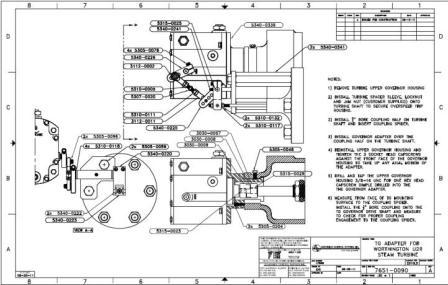

MSHS offers replacement parts for Gerhardt adapters and other similar designs.

See the below table for examples of custom designed mechanical actuation modifications and adaptations.

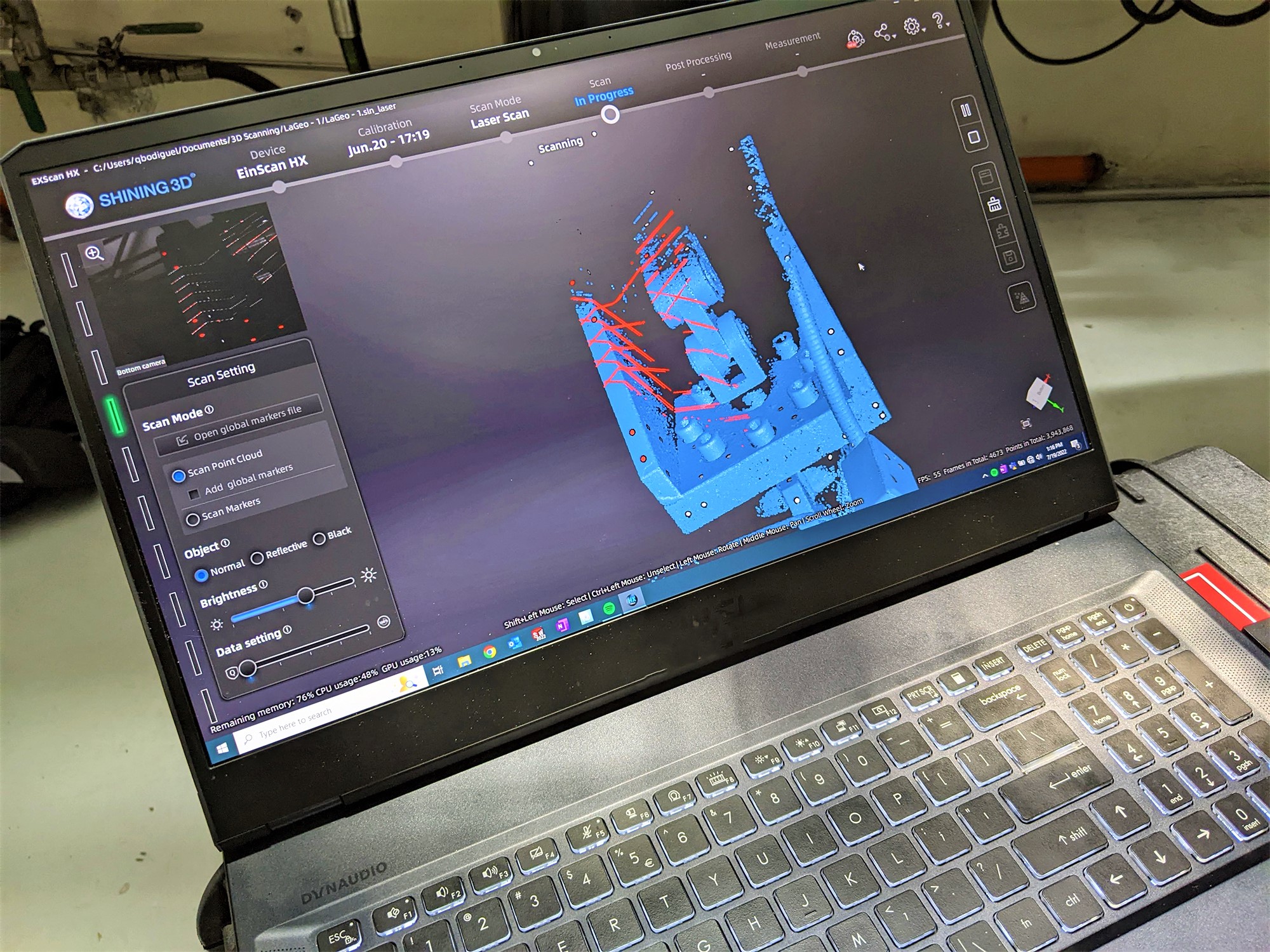

MSHS engineers can go on-site to utilize a no-contact state-of-the-art 3D Scanning and Digitization laser-based technology that enables teams to quickly generate precise and detailed (up to 3 million touch points) 3D CAD models of physical turbine/engine components. Resulting in Solid Works ready designs that development teams can use to reverse engineer components for accurate design specifications. Faster, more accurate equals greater value ensuring your operations are efficient with less downtime.

An object’s quick 3D scan can be compared to the original CAD model to identify inconsistencies for rapid assessments and corrective actions regarding wear, defects, warping, and twisting. Existing or damaged parts can be scanned to create functional CAD models and drawings in support of legacy equipment or equipment with insufficient documentation allowing teams to reverse engineer or redesign critical parts for customers’ systems ensuring their business keep moving!

Full service locations in Southeast, the Gulf Coast, and the Pacific Northwest, plus a network of local representatives throughout the Americas and the Caribbean.

Estamos disponible para servirle

Instalaciones de servicio completo en el Sureste; Costa Noroeste, y El Golfo. Además una red de agentes en

América Latina y el Caribe.

Please complete the form below. Non-Emergency Requests Only.

Specializing in turnkey engine services, control systems, and engineered solutions for the Marine, Industrial, Energy, and Defense/Government Sectors, MSHS is ready to serve you!