- Company

- Services

- Products

- Spare Parts

- Logistics

- Training/Classes

- Contact

- Careers

Siloxanes are chemicals used extensively in industrial products such as lubricants and in personal care products. Nearly all digester and landfill gas contain one or more species of siloxanes. When biogas containing siloxanes is combusted in gas turbines, boilers, fuel cells, or internal combustion engines, silicon dioxide collects on all equipment surfaces. Typical siloxane damage: abrasion, wear, coating and plugging to valves, spark plugs, pistons, cylinder heads, and catalytic converters.

Siloxane damage can be severe, causing frequent equipment maintenance and reduced generation capacity. Downtime increases and maintenance repair costs escalate for engine component cleaning, replacement, and overhaul.

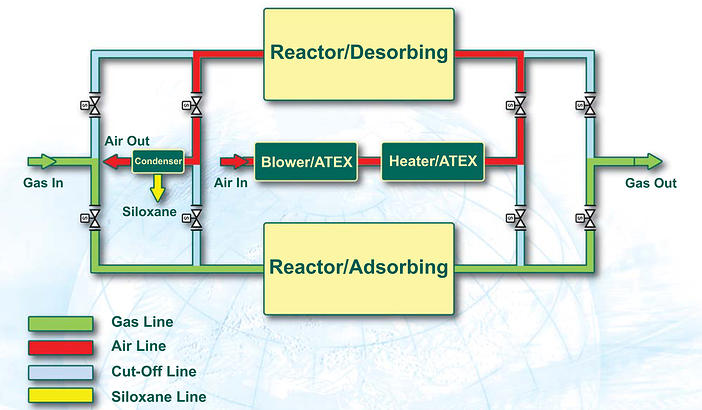

DCL’s SRT system is an advanced gas pre-treatment and purification system that is designed to remove harmful siloxanes from the gas supply. DCL uses a unique adsorption process that is cost effective and efficient. Manufactured with high quality stainless steel and a patented removal media, DCL’s SRT System is available in vertical or horizontal configurations.

Full service locations in Southeast, the Gulf Coast, and the Pacific Northwest, plus a network of local representatives throughout the Americas and the Caribbean.

Estamos disponible para servirle

Instalaciones de servicio completo en el Sureste; Costa Noroeste, y El Golfo. Además una red de agentes en

América Latina y el Caribe.

Please complete the form below. Non-Emergency Requests Only.

Specializing in turnkey engine services, control systems, and engineered solutions for the Marine, Industrial, Energy, and Defense/Government Sectors, MSHS is ready to serve you!