Turbocharger Repair & Maintenance

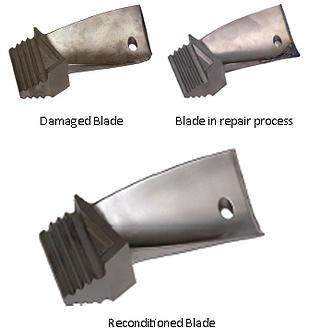

Reconditioning

MSHS offers a comprehensive package of repair solutions, tailor made for turbochargers in its turbocharger reconditioning center. We focus on providing reliable and cost-effective solutions which would include a comprehensive failure analysis using Non-Destructive Testing (NDT) method.

We offer inspection (NDT) and reconditioning for the following components:

- Turbine blades

- Turbine wheels

- Impellers and Inducers

- Shaft ends

- Shaft Journals

- Nozzle rings

Field Service

- 24/7 emergency response limits downtime

- Custom-designed maintenance solutions

- Trained & experienced field service engineers

- Long-term service agreements

Workshop Services

- Dynamic balancing of rotors & shafts

- Material cleaning & handling according to OEM guidelines

- Reconditioning of core components: Turbine blades, radial turbines, compressor wheels, inducers, impellers, shafts, re-blading rotors, journals & replacement of gland strips

- Segregated working areas minimize contamination & improve overall quality & responsiveness

- Troubleshooting, 24/7 emergency service

- Complete overhauls of all turbocharger brands

- Detailed repairs

In-house Capabilities

Using superior technology, our turbocharger division offers the highest level of component reconditioning. The reconditioning center is comprised of three independent workstations that are environmentally controlled to maximize efficiency and quality:

- NDT/quality control room

Equipment inspection/ defects diagnosed - Welding room

Components individually worked & re-built - Machining/ profiling room

Re-shape & finish

Qualified Service and parts

- Accelleron (formerly ABB)

- MAN

- PBS

- Caterpillar